Introduction

Winnowing Method is an age-old separation technique that has been utilised for millennia in the realm of separation techniques. This article delves into the intriguing process of winnowing, including its classic and modern methods, uses, benefits, obstacles, and limits.

What is Winnowing?

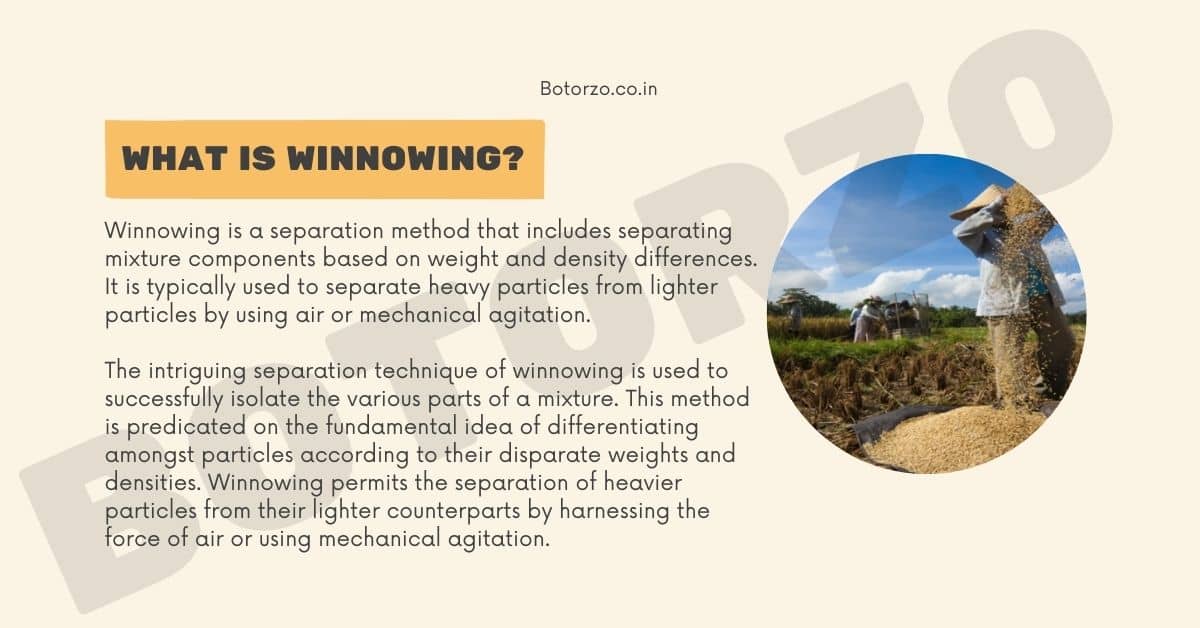

Winnowing is a separation method that includes separating mixture components based on weight and density differences. It is typically used to separate heavy particles from lighter particles by using air or mechanical agitation.

The intriguing separation technique of winnowing is used to successfully isolate the various parts of a mixture. This method is predicated on the fundamental idea of differentiating amongst particles according to their disparate weights and densities. Winnowing permits the separation of heavier particles from their lighter counterparts by harnessing the force of air or using mechanical agitation.

Winnowing History

One of the first known processes of separation, winnowing has a history dating back thousands of years. This antiquated method was crucial to the advancement of human civilizations, especially in the field of agriculture.

Early agricultural practices reveal the beginnings of winnowing when people realised they needed to separate the valuable grains from the undesirable chaff and other contaminants. The quality and purity of the crops that were gathered were largely depended upon by ancient civilizations including the Egyptians, Greeks, and Romans through the use of winnowing.

Winnowing began as a straightforward but efficient operation. The harvested crop, which often consisted of grains with their husks still on or surrounded by chaff, was thrown into the air or stirred up in a way that let the wind take over. The lighter chaff and other unwanted materials would be carried away by the breeze, leaving the heavier grains behind. To obtain the best separation, this manual winnowing method requires expertise and experience.

Techniques for winnowing improved along with agricultural practices. To better maintain control over the separating procedure, woven baskets were used. The basket was slanted to let the wind blow away the lighter chaff particles while the mixture of grains and chaff was repeatedly flung into the air. In comparison to the simpler hand winnowing technique, this process, known as basket winnowing, gave better accuracy.

The Process of Winnowing

Traditional Winnowing Methods

- Hand-Winnowing

- Basket-Winnowing

Hand Winnowing

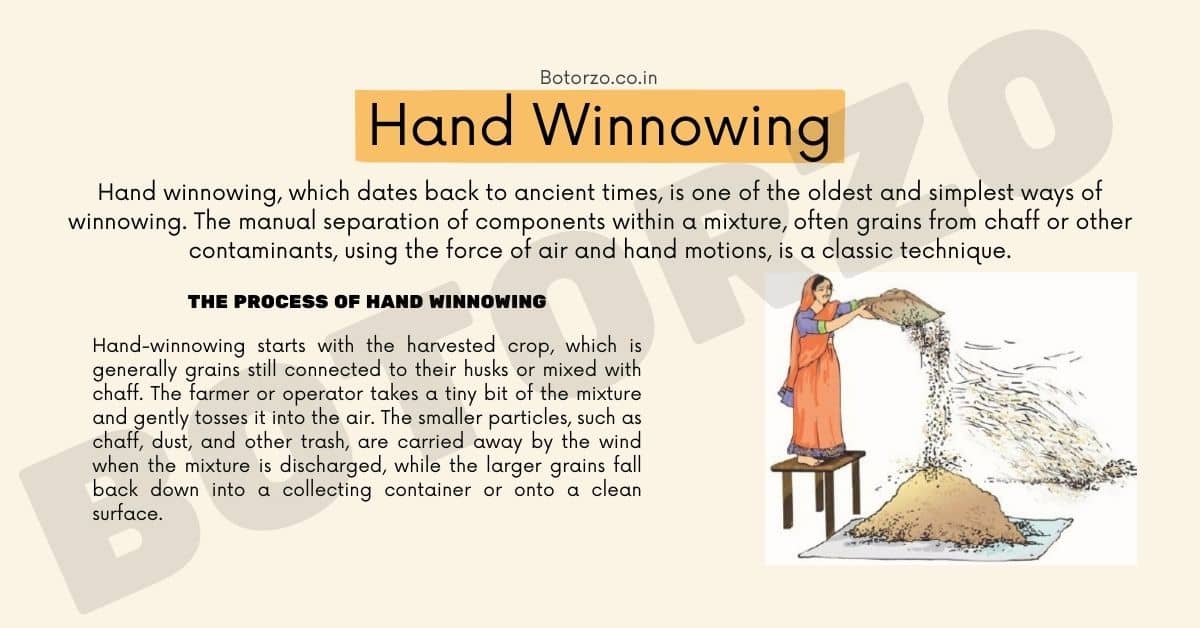

Hand winnowing, which dates back to ancient times, is one of the oldest and simplest ways of winnowing. The manual separation of components within a mixture, often grains from chaff or other contaminants, using the force of air and hand motions, is a classic technique.

The process of hand winnowing

Hand-winnowing starts with the harvested crop, which is generally grains still connected to their husks or mixed with chaff. The farmer or operator takes a tiny bit of the mixture and gently tosses it into the air. The smaller particles, such as chaff, dust, and other trash, are carried away by the wind when the mixture is discharged, while the larger grains fall back down into a collecting container or onto a clean surface.

Advantages of Hand Winnowing:

- Cost-effective: Hand-winnowing is a low-cost approach that requires nothing in the way of equipment or machinery. It is affordable to farmers with minimal resources and may be completed using simple tools.

- Portability: Hand-winnowing is very portable since it does not require big gear or infrastructure. Farmers may readily carry out the procedure in a variety of settings, making it appropriate for small-scale or mobile agricultural operations.

- Tradition preservation: Hand winnowing has significant cultural and historical value. Farmers may conserve cultural heritage and stay connected to their agricultural roots by using this ancient practice.

- Skill development: Hand winnowing requires skill and experience to achieve effective separation. Farmers who engage in hand winnowing can develop their expertise over time, improving their ability to assess grain quality and ensure optimal separation.

Disadvantages of Hand Winnowing:

- Labour-intensive: Hand-winnowing can be physically demanding, especially when dealing with large volumes of grain. The repetitive motion of tossing the mixture and the need for manual control can result in fatigue and slower processing times.

- Limited efficiency: Compared to modern mechanical winnowing methods, hand winnowing is less efficient in terms of throughput and precision. It may take more time and effort to achieve the desired level of separation, especially with larger quantities of grain.

- Weather dependency: Hand-winnowing relies on natural forces, such as wind, to carry away the lighter particles. Therefore, the effectiveness of hand winnowing can be influenced by weather conditions, including wind speed and direction. Unfavourable weather conditions may hinder the process or require farmers to wait for suitable conditions.

- Inconsistent results: Hand-winnowing heavily relies on the operator’s skill and judgment. Inexperienced operators or variations in the tossing technique may lead to inconsistent separation results, affecting the quality and purity of the final grain product.

It is crucial to remember that the unique context and requirements of the agricultural operation should be taken into account while weighing the benefits and drawbacks of manual winnowing. Even if hand winnowing has drawbacks, small-scale farmers or others who respect the cultural and traditional components of the practice can nevertheless benefit from it.

Basket Winnowing

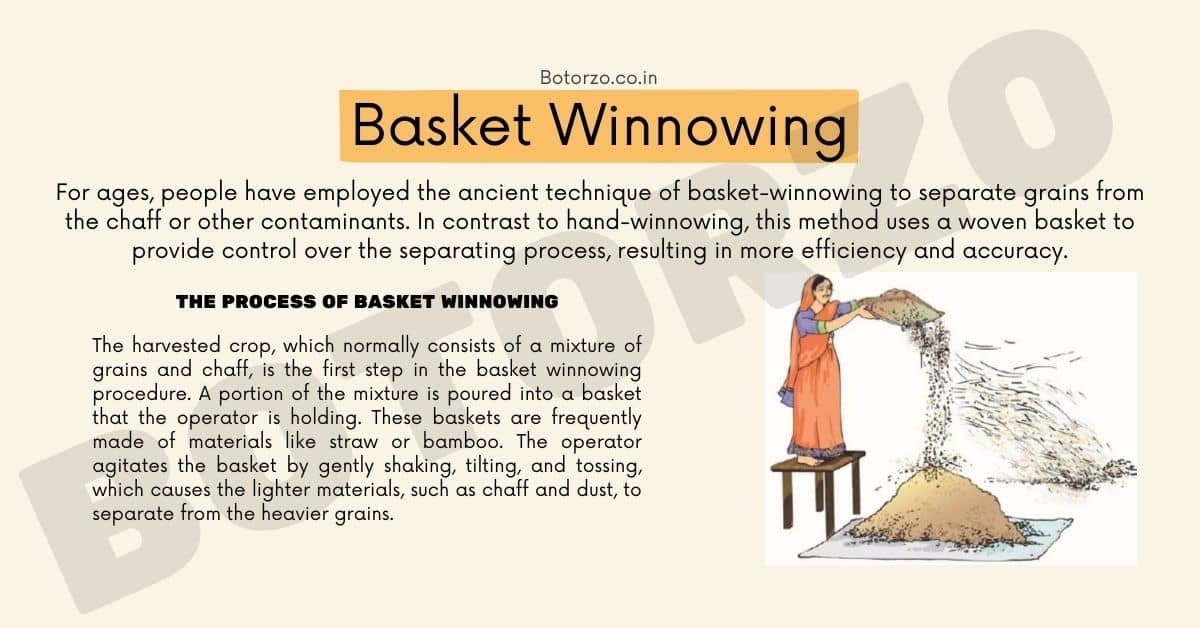

For ages, people have employed the ancient technique of basket-winnowing to separate grains from the chaff or other contaminants. In contrast to hand-winnowing, this method uses a woven basket to provide control over the separating process, resulting in more efficiency and accuracy.

The process of basket winnowing

The harvested crop, which normally consists of a mixture of grains and chaff, is the first step in the basket winnowing procedure. A portion of the mixture is poured into a basket that the operator is holding. These baskets are frequently made of materials like straw or bamboo. The operator agitates the basket by gently shaking, tilting, and tossing, which causes the lighter materials, such as chaff and dust, to separate from the heavier grains.

advantages of Basket winnowing

Basket-winnowing offers several advantages over other methods of winnowing:

- Enhanced control: The use of a basket provides greater control over the separation process. The operator can adjust the angle, speed, and intensity of shaking or tossing to achieve the desired separation results.

- Improved precision: The woven structure of the basket allows for more precise separation. It retains the grains while allowing the lighter particles to be carried away by the wind, resulting in cleaner and purer grains.

- Traditional craftsmanship: Basket-winnowing carries cultural and historical significance. The craft of weaving baskets for winnowing has been passed down through generations, preserving traditional skills and techniques.

- Accessibility: Basket winnowing is accessible to farmers with limited resources. The baskets can be crafted from locally available materials, making it a cost-effective option for small-scale farming operations.

disadvantages of Basket winnowing

However, basket winnowing also has its limitations:

- Manual labour: Like other manual winnowing methods, basket winnowing can be labour-intensive, requiring physical effort and repetitive motion. It may not be suitable for large-scale operations where mechanized alternatives are more efficient.

- Weather dependency: Basket-winnowing relies on natural airflow and wind to carry away the lighter particles. The effectiveness of the process can be influenced by weather conditions, such as wind speed and direction, making it dependent on favourable weather for optimal results.

- Skill and experience: Basket winnowing requires skill and experience to achieve consistent and efficient separation. The operator must possess a good understanding of the mixture’s characteristics and know how to manipulate the basket to achieve the desired results.

Modern Winnowing Methods

Mechanical Winnowing

Mechanical winnowing utilizes machines equipped with sieves and fans to separate the components. The mixture is fed into the machine, where the sieves separate the heavier particles from the lighter ones. The lighter particles are then blown away by the fans, leaving behind the desired product.

Air Winnowing

Air winnowing involves passing the mixture through a stream of air, causing the lighter particles to be carried away while the heavier ones fall down. This method is commonly used in industries such as food processing and pharmaceuticals, where precision separation is required.

Applications of Winnowing

Winnowing, as a method of separation, finds extensive applications across multiple industries. Its effectiveness in separating components based on variations in weight and density makes it a valuable technique in various fields. Here are some notable applications of winnowing:

- Agriculture

- Food Processing

- Mining

- Recycling

- Environmental Remediation

- Seed Cleaning

- Particle Size Classification

Agriculture: Winnowing plays a crucial role in agriculture, particularly in the processing of grains and seeds. It is employed to separate the edible grains from chaff, husks, or other impurities. By eliminating unwanted materials, winnowing improves the overall quality and market value of agricultural products.

Food Processing: The food processing industry utilizes winnowing to separate different components of food products. For example, it is employed to remove the outer shells or skins from nuts like almonds or peanuts. In the production of cocoa, winnowing aids in the separation of cocoa nibs from the husks.

Mining: Winnowing is an important technique in the mining industry for extracting valuable minerals from ore or separating minerals based on their densities. By subjecting the ore to winnowing techniques, heavier minerals can be separated from lighter gangue materials, facilitating the extraction and purification processes.

Recycling: Winnowing is utilized in recycling processes to separate different types of materials based on their densities. It aids in the segregation and recovery of recyclable components, such as separating plastics from other waste materials. Winnowing contributes to efficient recycling practices by selectively removing pollutants.

Environmental Remediation: Winnowing techniques are applied in environmental remediation projects. They assist in separating contaminated soil or sediment from debris or other non-contaminated materials. Winnowing helps in the restoration and cleanup of contaminated sites by selectively removing pollutants.

Seed Cleaning: Winnowing is widely employed in seed cleaning operations to remove inert materials, weed seeds, and other impurities from harvested seeds. This process ensures the purity and quality of seeds for planting.

Particle Size Classification: Winnowing methods can be used for particle size classification in industries such as pharmaceuticals, chemicals, and cosmetics. By subjecting the mixture to controlled airflow or mechanical agitation, particles of different sizes can be separated, enabling precise sorting and classification.

Archaeology: In archaeological excavations, winnowing is used to separate artifacts and cultural materials from soil and sediment. It aids in the recovery and preservation of delicate artifacts while eliminating unwanted materials.

Conclusion

Winnowing, a time-honored method of separation, continues to find relevance in various industries today. From its humble origins in ancient civilizations to modern mechanical techniques, winnowing enables the efficient separation of components based on weight and density differences. Its applications in agriculture, food processing, mining, and pharmaceuticals showcase its versatility and significance. While winnowing offers several benefits, it is essential to address its limitations and adapt to modern technologies for optimal efficiency. With its sustainable and cost-effective nature, winnowing remains a valuable tool in the pursuit of separation.

Frequently Asked Questions

What is the main purpose of winnowing?

Winnowing is primarily used to separate components of a mixture based on their weight and density differences.

What are some traditional winnowing methods?

Traditional winnowing methods include hand winnowing and basket winnowing.

How does modern mechanical winnowing work?

Modern mechanical winnowing involves the use of machines equipped with sieves and fans to separate the components based on weight and density.

What are the applications of winnowing in the food industry?

Winnowing is widely used in the food industry to separate impurities from food products, such as separating cocoa nibs from husks in cocoa processing.

Is winnowing an environmentally friendly method?

Yes, winnowing is considered environmentally friendly as it relies on natural forces like air and gravity and does not require the use of chemicals.

Our Another Domains Vidyapedia.in