Threshing Method is an important stage in the separation of grains from harvested crops. For ages, it has been an essential aspect of agriculture, helping farmers to extract valuable grains from crops such as wheat, rice, barley, and others. In this post, we’ll look at this method ranging from classic manual processes to current mechanised ones. We will also look at the elements that influence separation efficiency, the significance of effective methods of separation, as well as the problems and potential developments in this subject.

Introduction

Threshing is a key agricultural procedure that includes the separation of edible grains from the harvested crop. Threshing’s primary goal is to separate the grain from the rest of the plant, such as straw, husks, or chaff. This separation allows farmers to gather the precious grains and prepare them for a variety of uses, including consumption, seed production, or sale.

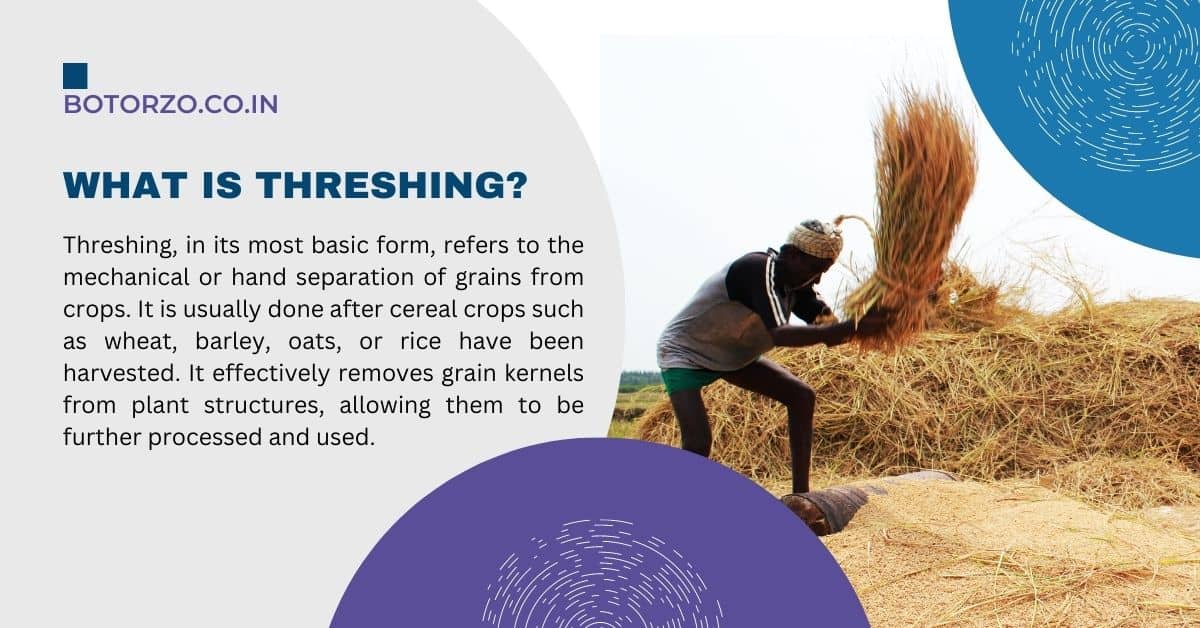

What is Threshing?

Threshing, in its most basic form, refers to the mechanical or hand separation of grains from crops. It is usually done after cereal crops such as wheat, barley, oats, or rice have been harvested. It effectively removes grain kernels from plant structures, allowing them to be further processed and used.

Historical Background of Threshing

Throughout history, threshing has been an important agricultural practice. Manual techniques were used in ancient times, with farmers using various equipment to separate the grains from the harvest. Flails, which were wooden rods with connected beaters, and animal treading, in which cattle trampled over the crop to release the grains, were examples of these implements.

Traditional Threshing Methods

- Hand Threshing

- Flail Threshing

- Treading Threshing

- Threshing by Animals

Hand Threshing

Hand-threshing entails manually separating grains from the harvest. It is a time-consuming procedure in which workers beat the harvested crop with sticks or instruments to dislodge the grains. Hand-threshing is still practised in some areas with limited resources or on a local scale.

Flail Threshing

Another manual method employed in traditional farming is flail-threshing. It employs a wooden handle with a hinged stick connected to it, which is thrown violently against the gathered crop. The stick strikes the crop as it swings, releasing the grains from the plant. Flail-threshing necessitates physical effort and is best suited for lesser quantities of harvested crops.

Treading-Threshing

Treading threshing is an ancient process in which animals such as cattle or horses trample over the harvested crop. The weight and movement of the animal aid in the separation of the grains from the straw or husks. Before the introduction of mechanised processes, treading-threshing was a prevalent practice in many agricultural communities.

Threshing by Animals

Animals such as oxen or donkeys are still used for separation in some locations, particularly in isolated areas or underdeveloped countries. The animals are trained to walk in a circular pattern while dragging a heavy wooden board or stone roller across the crop. The animals’ pressure helps to break down the plant material and separate the grains.

Mechanized Threshing Techniques

With the advancement of technology, manual separation methods have been largely replaced by mechanized techniques. These modern methods offer higher efficiency, increased productivity, and reduced labor requirements. Let’s explore some of the common mechanized separation techniques:

- Threshing Machines

- Combine Harvesters

- Impact of Mechanization

Threshing Machines

Threshing machines revolutionized the agricultural industry by automating the separation process. These machines feature a rotating drum or cylinder with teeth or beaters that strike the crop, causing the grains to separate from the plant material. The crop is fed into the machine, and the separated grains are collected while the straw or husks are expelled as waste. Threshing-separation machines are capable of handling larger volumes of crops, significantly reducing labour requirements and improving efficiency.

Combine Harvesters

Combine harvesters are versatile machines that perform multiple tasks in one operation. They combine the processes of harvesting, threshing, and winnowing. The combined harvester cuts the crop, separates the grains from the straw, and collects the grains in a storage tank while simultaneously discarding the remaining plant material. These machines are widely used in large-scale farming operations, particularly for cereal crops like wheat, corn, and soybeans.

Impact of Mechanization

The introduction of mechanized threshing techniques has had a profound impact on agriculture. It has led to increased production efficiency, reduced post-harvest losses, and improved overall crop quality. Mechanization has also helped to alleviate the labour-intensive nature of separation, allowing farmers to focus on other aspects of farming and increasing productivity.

Modern Threshing Innovations

Continued advancements in agricultural technology have led to the development of more sophisticated and specialized threshing methods. These innovations aim to further enhance efficiency and productivity. Let’s explore some of the modern techniques:

- Axial-Flow Threshing

- Rotary Threshing

- Drum Threshing

Axial-Flow Threshing

Axial-flow threshing is a method that utilizes a rotating rotor and concave system. The crop is fed into the machine, and the rotor’s helical blades separate the grains from the straw. The separation occurs as the crop moves along the rotor’s length, guided by concave plates. This method ensures gentleness and efficiency, minimizing grain damage and increasing overall productivity.

Rotary Threshing

Rotary threshing involves the use of a cylindrical drum with protruding bars or teeth. The crop is fed into the drum, and the rotating motion causes the grains to separate from the plant material. The separated grains pass through perforations in the drum, while the remaining straw or husks are expelled. Rotary threshing is known for its high-speed operation and excellent efficiency.

Drum Threshing

Drum threshing utilizes a large drum with slanted or curved paddles inside. The crop is fed into the drum, and as it rotates, the paddles gently beat the crop, causing the grains to separate. The separated grains pass through perforations in the drum, while the straw or husks are discharged separately. Drum threshing is commonly used for crops with delicate grains that require a more careful process.

conclusion

Threshing, as a method of grain separation, has evolved significantly over time. From traditional manual techniques to modern mechanized approaches, the goal remains the same – to efficiently separate valuable grains from the harvested crop. Mechanized methods have revolutionized agriculture, increasing productivity and reducing labour requirements.

Factors such as moisture content, cylinder speed, and grain variety impact the efficiency of threshing. Ensuring efficient separation is crucial for maintaining grain quality and maximizing yield. Its practices vary globally, with traditional methods still being employed in developing countries and modern techniques dominating in developed nations.

Challenges such as sustainability and environmental concerns are driving the development of eco-friendly and precision threshing technologies. Automation and AI are also playing a significant role in enhancing processes. As the agricultural industry progresses, continuous innovation in threshing methods will contribute to improved efficiency, reduced environmental impact, and enhanced food production.

Frequently Asked Questions

What is the purpose of threshing?

Threshing is the process of separating grains from harvested crops. Its purpose is to extract valuable grains from the rest of the plant material for various uses, such as food production, seed propagation, or sale.

How does mechanized threshing improve efficiency?

Mechanized threshing techniques, such as machines and combine harvesters, offer higher efficiency by automating the separation process. They can handle larger volumes of crops, reduce labour requirements, and achieve more precise separation, resulting in improved productivity.

What are the common crops that undergo threshing?

Crops such as wheat, rice, barley, oats, corn, and soybeans are among the common crops that undergo threshing to separate the grains.

Can threshing methods vary for different grain varieties?

Yes, different grain varieties may require adjustments in threshing methods. Factors like grain size, shape, and hardness influence the settings of the separation equipment to achieve optimal separation.

Are there any alternatives to traditional threshing methods?

Mechanized separation techniques have largely replaced traditional methods. However, ongoing research and technological advancements aim to develop sustainable and efficient alternatives, such as precision threshing and AI-driven systems, to further enhance grain separation processes.

Our Another Domains Vidyapedia.in And Uietmdu.in