Introduction

In the field of control systems, several sorts of systems are used to monitor and regulate processes. The open loop system is one example. This page tries to provide a full explanation of open-loop systems, their operating principles, advantages, weaknesses, applications, and a comparison with closed-loop systems. So, let us go into the area of open-loop systems and investigate their significance.

Open Loop Control System

Understanding Control Systems

Before delving into open loop systems, it’s critical to understand control systems. Control systems are used to maintain a process’s or system’s desired conditions or performance. These systems are made up of components that accept inputs, process them, and provide outputs to regulate the behaviour of the system. There are two types of control systems: open-loop systems and closed loop systems.

Read More Content From Control System

Definition and Components of an Open Loop System

A non-feedback system, also known as an open-loop system, is a form of control system in which the output has no effect on the control action. In other words, it lacks the ability to detect and alter output based on desired results. An open loop system’s basic components are as follows:

- Input: The input is the desired command or set point given to the system.

- Process: The process represents the system or device being controlled.

- Controller: The controller determines the control action based on the input and predefined characteristics.

- Actuator: The actuator translates the control action into physical changes in the system.

- Output: The output is the result or response generated by the system.

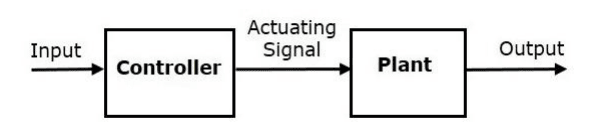

Here, a controller receives an input and outputs an actuating signal or regulating signal. A plant or process that has to be regulated receives this signal as an input. Thus, the plant generates a controlled output. An illustration of an open loop control system is the traffic light regulation system that we previously covered.

Working Principle of an Open Loop System

An open loop system’s operation follows a very simple concept. The controller chooses the control action after receiving the input without taking the system’s output into account. A response or output results from the actuator carrying out the necessary activity in response to the control action. The output is not measured or compared to the intended outcome by the system, though. As a result, any process irregularities or disturbances might not be fixed, giving the system limited control.

Examples of Open Loop Systems

Open loop systems are commonly found in various applications, including:

- Washing Machines: The washing machine operates based on pre-set programs without monitoring the washing process.

- Traffic Signal Systems: Traffic signals follow pre-determined timing patterns, regardless of the traffic conditions.

- Irrigation Systems: Irrigation systems may have pre-defined schedules for watering plants without considering soil moisture levels.

Challenges and Limitations of Open Loop Systems

While open loop systems serve specific purposes, they face certain challenges and limitations:

- Inaccuracy and Uncertainty: Deviations in the process or external disturbances can significantly affect output accuracy.

- Limited Control: Open loop systems lack the ability to adapt to changing conditions or correct errors, limiting their control capabilities.

- Environmental Factors: Open loop systems are sensitive to environmental factors such as temperature, humidity, and external interferences.

Advantages of Open Loop Systems

Open loop systems offer certain advantages in specific applications:

- Simplicity: Open loop systems are relatively simple and cost-effective to implement.

- Fast Response: Since there is no feedback loop, open-loop systems can provide a faster response time.

- Stability: These systems are generally stable due to the absence of feedback-induced oscillations.

Closed loop Control system

A closed loop system, also known as a feedback system, is a form of control system that compares the system’s output to the desired set point via feedback. It constantly checks the output and modifies the control action based on feedback.

Working Principle of a Closed Loop System

The working principle of a closed loop system involves continuous monitoring and adjustment based on feedback. Once the input is provided, the system compares the actual output from the sensor with the desired set point. The controller analyzes the difference (error) between the actual and desired values and generates a control action to minimize the error. The actuator then implements the control action, resulting in a modified output. This feedback loop ensures that the system dynamically adapts to changes and maintains the desired conditions.

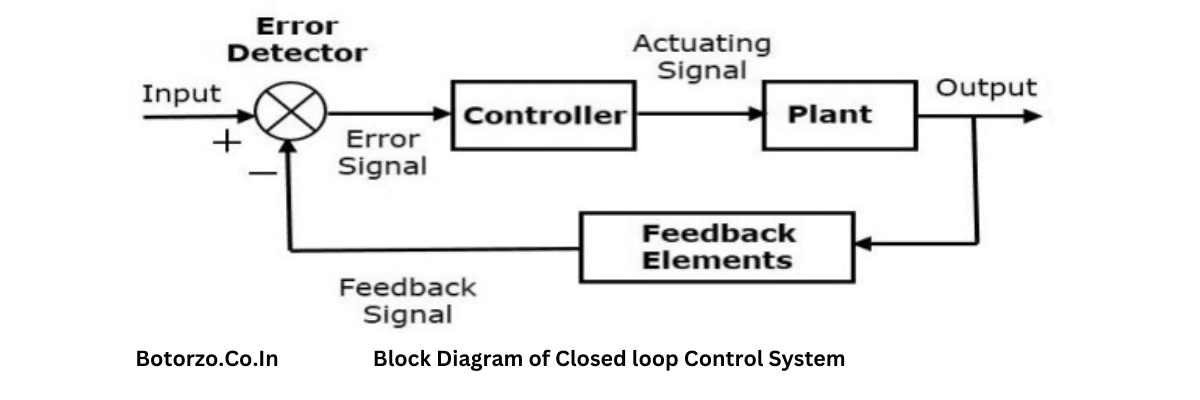

The output of a closed loop control system is sent back into the input. As a result, the control action is determined by the desired output.

The block diagram of a negative feedback closed-loop control system is shown in the picture below.

The difference between the input signal and the return signal is the error signal that the error detector generates. The block (feedback elements) produces this feedback signal by considering the output of the entire system as an input. The error signal is applied as an input to a controller in place of the direct input.

So, the controller generates an actuation signal that the plant responds to. In this configuration, the control system’s output is automatically modified until the desired reaction is obtained. Therefore, automatic control systems is another name for closed-loop control systems. A closed-loop control system is exemplified by a traffic light control system with a sensor at the input.

The Benefits of Closed Loop Systems

Closed-loop systems have various advantages over open-loop systems, including the following:

- Enhanced Accuracy: The feedback mechanism enables closed-loop systems to compare the output to the desired set point in real time, resulting in increased accuracy and precision.

- Robustness: Because closed-loop systems may dynamically alter the control action to overcome deviations, they are more resilient to disturbances and uncertainty.

- Closed loop systems can adapt to changes in the process or system conditions by changing the control action based on real-time feedback.

Comparison between Open Loop and Closed Loop Systems

The differences between the open-loop and the closed-loop control systems are as follow:

| Open-Loop Control Systems | Closed-Loop Control Systems |

|---|---|

| The feedback path is not present. | These are also called feedback control systems. |

| The feedback path is present. | The control action is dependent of the desired output. |

| The control action is dependent on the desired output. | These are also called non-feedback control systems. |

| Easy to design. | Difficult to design. |

| These are economical | These are costlier. |

| Inaccurate. | Accurate. |

Conclusion

In conclusion, open loop systems are a type of control system where the output does not affect the control action. They find applications in scenarios where simplicity and cost-effectiveness are prioritized over precise control. While open-loop systems offer advantages such as simplicity and fast response, they also come with limitations in terms of accuracy and adaptability. Understanding the characteristics, advantages, and disadvantages of open-loop systems is essential for designing efficient control systems for various applications.

Read More Engineering Content From Engineeringadda.in

Frequently Asked Questions (FAQs)

What are the main advantages of closed-loop systems?

The main advantages of closed-loop systems include enhanced accuracy, robustness in the face of disturbances, and adaptability to changing conditions.

How does a closed-loop system work?

The system compares the actual output with the desired set point using feedback, adjusting the output accordingly.

How do they compare to open-loop systems?

Closed-loop systems utilize feedback, and offer higher accuracy; open-loop systems lack feedback.

What is the main difference between open-loop and closed-loop systems?

Open loop systems lack feedback mechanisms and do not adjust the output, while closed loop systems utilize feedback to continuously monitor and adjust the output.

Examples of closed-loop systems?

HVAC thermostats, robotic control, automotive cruise control.